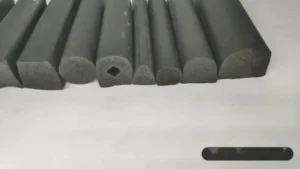

Adhesives are vital in industries like automobile manufacturing. There are a myriad of adhesives, the SBR stick (Styrene-Butadiene Rubber) is one of the most adaptable and extensively used substances.The SBR stick is known for its versatility, strength and moderateness, the SBR leave accompanies various benefits which make it an extraordinary option for some areas.

In this piece we’ll examine the main five advantages from SBR sticks, frame their purposes, and uncover the justifications for what reason they’re an optimal decision in modern conditions.

Exceptional Durability and Flexibility of SBR Stick

Perhaps of the greatest positive viewpoint that accompanies SBR sticks lies in their exceptional perseverance. SBR is a counterfeit elastic with predominant sturdiness against mileage, which makes it proper for conditions with high pressure. Rather than normal elastic which is helpless to corruption within the sight of unforgiving ecological circumstances, SBR stick keeps up with its quality even in outrageous tensions and temperatures.

Temperature obstruction: SBR sticks can endure a broad temperature range including frosty temperatures and very hot conditions without losing the properties of glue. They are an extraordinary answer for indoor and outside utilizes.

Substance Safe: The synthetic idea of SBR can make it resistive to various synthetic substances, oils and solvents. This is a pivotal property in the auto business and development, where openness these substances is very successive.

Flexibleness: Other than being solid, SBR sticks are adaptable which permits them to join protests that go through movement or vibration. This makes them sturdy for bond even in upsetting conditions like auto gatherings and weighty hardware.

2. Flexibility in Applications

The reach that accompanies SBR sticks is one more variable to their inescapable use. As well as holding plastics and metals to attaching wood, elastic or texture SBR sticks can deal with different sorts of materials and surface.

Auto Industry: Inside the car area, SBR sticks are utilized to bond elastic gaskets, seals, as well as trim parts. Their flexibility as well as ability to withstand chemicals and oils makes them a great adhesive for automobile production and repair.

Construction:In the construction industry, SBR sticks are used for a myriad of reasons, including cement bonding, waterproofing as well as adhesive tiles. Their resistance to water and the ability to join different materials make them popular by contractors.

Shoes: SBR sticks are often used in the industry of footwear to join rubber soles with uppers. They are able to form the strongest, most flexible glue that can stand up to the demands of everyday wear is a huge benefit for shoe makers.

Upholstery and Textile: In the upholstery and textile industries, SBR sticks are used to join textiles, padding and leather. The cement’s adaptability ensures that the materials reinforced keep up with their regular movement fundamental for strength and solace.

3. Cost-Viability

In the enterprises where gigantic amounts of cements are required, costs are consistently a critical viewpoint to consider. SBR sticks are prestigious to be a financial plan cordial element with no think twice about quality.

Lower Material Expenses: Since it will be it is an engineered substance, SBR is frequently less exorbitant to produce when contrasted with regular elastic or different cements with elite execution. Its moderateness is an optimal choice for modern tasks of enormous scope when financial plan impediments are an issue.

Effectiveness: SBR sticks are easy to use, which reduces labor duration and cost. They are quick-setting, which reduces interruptions, which means that projects are completed quickly.

Long-Lasting Bonds SBR sticks are reasonably priced however they do not sacrifice high-quality. Their durable bonds minimize the requirement for regular repairs or reapplications, helping to save money over time.

4. Environmentally Friendly and Safe

In a time when environmental considerations are more important to many businesses, they seek eco-friendly alternatives. SBR sticks serve the environment with a green feature as compared to other adhesives due to the lower emission levels during the production process and when they are applied.

The low VOC emanations: Unpredictable Natural Mixtures (VOCs) are substance compounds delivered into the air when with specific glues. They might add to contamination in the air and make wellbeing risk. SBR sticks for the most part have less VOC emanation, which makes the more secure choice for workers as well as the indigenous habitat.

Recycling Material: SBR can be recycled and reduces total environmental impact. In products like flooring or tires The adhesive could be part of a recycled loop to help save resources and decrease consumption.

Non-toxic: SBR sticks are typically non-toxic and therefore appropriate to be used in sensitive places like schools, hospitals and even food processing manufacturing facilities. They are safe because their formulation guarantees they do not release hazardous chemical substances into the air.

5. Easy to Apply and Work With

The main benefit for SBR sticks is their simplicity in their use. In a factory environment or at the construction location SBR sticks serve an easy solution that does not require any specialized equipment or in-depth instruction.

Hot Melt Application SBR sticks are typically employed for hot melt applications, where the adhesive gets made to melt which is then sprayed onto the surfaces to be joined. This technique allows for an easy and quick application which allows workers to swiftly move from one job from one task to another.

Cold application: In specific cases, SBR sticks can be utilized without warming, together simple compression or moving to bring off a cement. This considers greater versatility in how the glue is applied and makes it fitting for a variety of ventures and enterprises.

Consistency and Control SBR sticks provide consistency in results that are crucial in the industrial setting where precision is vital. They are controlled in their application to assure that an appropriate quantity of adhesive is applied to avoid waste, and ensure the strength of the bonds.

Common Uses of SBR Stick Across Industries

We’ll take a glance at the particular sectors in which SBR sticks are a big hit:

Automotive Industry

Bonding and sealing: SBR sticks are used in the auto business for bonding gaskets sealing materials, as well as insulation. They add an extremely durable and secure bond that is able to stand up to the tough environments encountered by automobiles.

Interior applications: The adhesive is also employed for gluing components of the interior like door panels, dashboards and trimmings.

Construction

In the field of construction, SBR sticks are used extensively for waterproofing, including the adhesive of membranes to concrete as well as different substrates.

Tile adhesive SBR is widely used in the industry of tile because it is resistant to humidity and also its flexible.

Footwear Manufacturing

Shoe Soles SBR sticks make a great adhesive to bond rubber soles of shoes to leather or fabric uppers providing durability and elasticity.

Sports Shoes: Athletic shoes, that require high elasticity and resistance to impact and abrasion resistance, is also dependent upon SBR-based adhesives.

Textile Industry

Fabric Bonding SBR sticks can be used for bonding fabric for furniture, upholstery as well as clothing.

Packaging and Labeling

Adhesive Labels SBR sticks are commonly employed in the industry of packaging to make label adhesives that resist to oil, water, as well as chemical exposure.

Picking the Right SBR Stick for Your Application

In settling on the best SBR stick to use for your venture, you ought to think about the accompanying angles:

Surface Similarity: Check you are together a SBR stick you are together is viable with the material you’re joining. Different formulations might work best on specific substrates like plastics, metals or textiles.

Specific Temperatures When you are working with extreme or low temperatures, be sure to select an SBR stick with a rating to the right temperature range.

Method of Application: Choose whether either a cold or hot melt application would be more appropriate for the needs of your business. Hot melt offers a quicker connection, whereas cold application could be better suited for materials that are sensitive.

Bond Strength: In industrial purposes the bond strength is an important factor. Be sure you choose an SBR stick you choose has sufficient strength to meet the specific application.

Conclusion

SBR sticks offer a flexible robust, cost-effective, and durable solution to a range of industrial needs. Their elasticity, resistance to chemicals and easy application make them the ideal option for various industries like construction, automobile, footwear as well as packaging.

When you understand the advantages that come with SBR sticks, it is possible to pick the appropriate glue for your needs and assure the longevity of a long-lasting, reliable bond. If you’re searching to find an adhesive that is able to stand up to extreme conditions, join various materials or offer an affordable solution SBR sticks provide the quality you’re looking for.